The ABC-2020 is a low-cost batch controller that is

extremely easy to use. There are many standard packages that include a valve

and meter with all components kept in-stock. Many special order systems with non-stock valves and meters are also available.

The ABC-2020 is a low-cost batch controller that is

extremely easy to use. There are many standard packages that include a valve

and meter with all components kept in-stock. Many special order systems with non-stock valves and meters are also available.

In order to select the best system for your application you have to make 3 selections.

1) The Meter

2) The Valve

3) The Resolution and Program

Once you have decided on the meter and valve type, you can select that combination using the Batching System Selection Chart. Then, when you land on the page for that combination, select the program, size, and accessories.

1) Selecting the best meter for your batching system

If the system will be for batching of clean water, then you will most likely want a mechanical water meter with a reed switch type pulse output. If you will be dispensing a liquid other than water, a MAG meter or Oval Gear meter will be needed. Here we will focus on clean water applications and our standard “Complete Batching System Packages”. If your batching application requires equipment not listed here, give us a call at 1-855-871-6091.

Types of Water Meters

Multi-jet

Multi-jet meters are required to be

installed horizontally with the register facing upwards. There are three

different series that are the same design other than the materials of

construction. They all offer various pulse rates to get the resolution that you

need: 10ths of a gallon, single gallons, 10 gallon, and 100 gallon.

Plastic body

lowest cost

½”, ¾”, 1”, and 1 ½” male NPT connections

Lead free brass body

½”, ¾”, 1”, 1 ½”, and 2” male NPT connections

Lead free brass body

special internals for hot water (up to 180˚F)

½”, ¾”, 1”,

1 ½”, and 2” male NPT connections

Positive Displacement (nutating disc)

Positive displacement meters can be installed in any orientation. Limited to 2 pulse rates: 1 pulse per

gallon or 1 pulse per 10 gallons.

Lead free brass body

½”, ¾”, 1” with male NPT connections

1 ½” and 2”

with 2-bolt oval flange connections

Many other meters are available – call 1-855-871-6091 for assistance.

2) Selecting the best valve for your batching system

The standard offering includes 2 distinct types of valves, each having its own advantages. We also offer batching systems that include a relay to control a customer provided pump rather than using a valve. Or you could also use BOTH a valve and a pump relay if needed.

1) Solenoid Valves

2) Ball Valves

Electric Ball

Valves

Ball valves are "full port" for

unrestricted flow which is ideal for large batches since they will complete

faster. They also close slowly which prevents water hammer.

EBV Series (Capacitive Return; 1/2”, 3/4”, 1” female NPT)

- Stainless steel valve and ball with Viton seals

- 3 second close time

- Power to open and charge the capacitor

- Stored energy from charged capacitor to close when power is removed

- Will fail to the closed position if power is lost

- No manual override

- Can be installed outdoors or in wash-down or dusty areas.

SM Series (reversing motor with control signal; 1 ½” and 2” female NPT)

- Lead free brass valve

- 7 second close time

- Constant power required

- Energize control signal to open, de-energize to close

- Will fail in place if power is lost

- Equipped with manual override

- FOR INDOOR USE ONLY - Call for alternative valves that are weatherproof

Solenoid Valves

These restrict flow

somewhat, but close instantly making them ideal for smaller batches where speed

is not a concern and accuracy is more important.

ESV series (1/2”, ¾”, and 1” female NPT)

- Stainless steel valve with Viton seals

- Instant closure

Air Operated

Ball Valves

The best of both

worlds! They are full port for unrestricted flow AND they close fast (typically

less than 1 second)

- SS, Brass, or PVC bodies (others available)

- reliable 80 psi air supply needed to actuate (A small compressor will work just fine)

Other Valve Types

In addition to the valves listed above, Flows.com can provide many other valve types.

- Angle Seat Valves (air operated)

- Coaxial Valves (air or electric)

- Plug Valves (air or electric)

- Butterfly Valves (air or electric)

- 3-way Ball Valves (air or electric - used for recirculating media when not dispensing a batch)

Many other valves are available – call 1-855-871-6091 for assistance.

3) Selecting the best resolution and program for your batching system

As a general rule of thumb, you should never select a resolution

finer than absolutely needed. Doing so will simply wear out the reed switch

faster while providing no great benefits. So, if you will be doing batches of

100, 150, and 200 gallons, there is NO reason to go with 10ths of a gallon. Single

gallons would work just fine. In fact… you could even go with 10 gallon

increments if your batch sizes will always be a multiple of 10.

There are a few considerations to be made when selecting the resolution

Batch Size

- The larger the batch size, the larger the increments can be.

- If all of the batch sizes are in multiples of 10 gallons, then there is no

reason to go with a finer resolution.

Accuracy Requirements

- If rounding up or down to the next larger increment will give you acceptable

results, there is no reason to go finer.

example: you need 47.5 gallons

- if 47 or 48 would be close enough, then go with whole gallons rather than

10ths

- if 50 would be close enough, you could even go with 10 gallons.

Flow Rate

There are 2 situations where the flow rate must be considered.

1) General Limitation of the ABC Controller

The ABC controller is limited to

2 pulses per second (which has some safety

factor built-in). This can be pressed to a bit above, but that is not recommended.

Going too fast allows the possibility for pulses to get missed, this will result

in getting MORE water than desired.

To easily figure out the pulse rate, multiply the flow rate in gpm by the pulses per gallon then divide that by 60. That will give you the pulses per second.

12 gpm x 10 pulses per gallon = 120 pulses per minute

120 pulses per minute divided by 60 sec = 2 pulses per second

This would be an acceptable application as long as the "End of Batch" considerations below are also acceptable.

2) "End

of Batch" Considerations

If using a ball valve, there is the “time to close” where the valve begins

closing at the exact set volume, and there will be some additional flow while

this happens. Actually, this will also happen when using a

solenoid valve, just on a much smaller scale.

There are 2 factors to note for this:

1. Any “overage” that is dispensed at the end of a batch is automatically subtracted from the next batch since it does get registered by the mechanical meter – so this overage is actually making up for what was missed in the beginning of the batch. This will provide accurate results as long as system conditions (like pressure and flow rate) remain constant.

example: you are batching in whole gallons, and while the valve closes

you end up getting 0.2 gallons extra. That 0.2 gallons DOES get registered by

the meter, so the first gallon of the next batch will actually only be 0.8

gallons. The end of the next batch will also get the 0.2 extra, therefore

making up for the missing 0.2 on the first gallon

.

2. BUT, if the amount of “overage” is larger than

your resolution's increment, only the last “partial increment” will be subtracted from the first

increment of the next batch. So, you may end up getting an extra increment or

2. This will be repeatable assuming that your system conditions do not change (pressure

and flow rate).

example: You are batching 25 gallons of water in whole gallons at a rate of 40

gpm.

- You are using an SM ball valve that takes 7 seconds to close completely.

- During that 7 seconds, an extra 2.66 gallons is getting dispensed.

In this case, setting the batch controller for 23 gallons would get you an

accurate 25 gallon batch.

Here’s how it would work:

The first gallon reported by the meter to the controller will really be only 0.33

gallons (because the last batch caused the meter to end up at 0.66). When the controller begins to close at 23 gallons (which is really

only 22.33), the system will again dispense the extra 2.66 gallons as the valve

closes.

The result is 22.33 + 2.66 = 25 gallons.

Lockout Feature

There are a few programs that include a

“Lockout” function. This simply means that the remote button can only be

used to dispense a single batch. It can start and stop the batch as it runs,

but once it completes or is cancelled, you cannot start another batch until

there is interaction with the main ABC controller to “unlock” it.

If you are not comfortable making these selections yourself, we are always happy to help you do so. Just give us a call at 1-855-871-6091 or submit THIS FORM with as much information as you can.

Selecting the Appropriate Accessories for Your Batching Systems

There are some accessories available to make your batching system complete. These accessories can be added to the systems as accessories, or ordered separately from their own dedicated pages.

Protective Installation Cabinet

The ABC controller is NOT waterproof or water resistant. If there is a chance that the controller will get rained on or splashed, or you are operating in a very dusty environment, this is a must. When ordered along with the batch controller, the controller will come preinstalled in the cabinet.

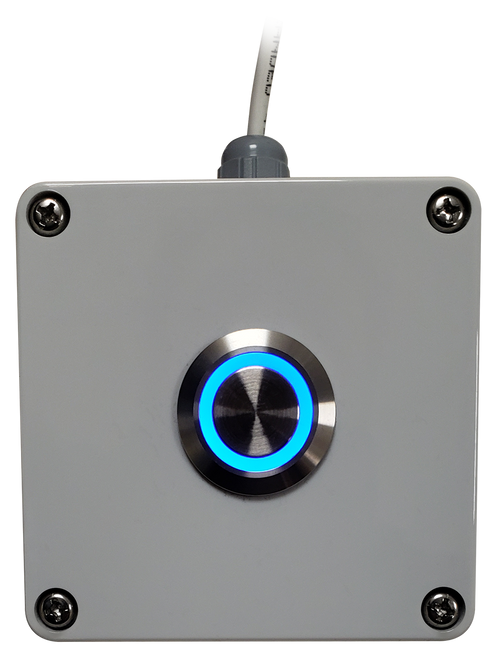

Remote Button

The remote button IS weatherproof, so it can be located in a wet or dusty environment. In fact, it is an "anti-vandal" button like those used on parking garage ticket dispensers, elevators, etc. It acts as a copy of the Big Blinking Blue Button™ which is used to start and stop batches.

The remote button is used for a few reasons:

- To provide an emergency stop in a location other than where the controller is

- To make use of the "Lockout" function where it is limited to dispensing one batch only

- To avoid having to open the protective cabinet in order to start or stop a batch

- To provide a more durable button for operators with messy fingers to use, thus protecting the ABC controller from that mess

Line Selector

The FLS-10 line selector provides for the use of up to 10 separate lines for input or output. It does so by diverting a common power source to one of (up to) 10 different valves or pumps. This power source can be constant, such as that provided by an included 12VDC wall plug transformer power cord, or it can be intermittent such as that provided by the ABC's "Valve" port. If the power source is constant, then the line selection system is separate from the batching system that will still require the main on/off valve. If you use the batch controllers output, then it becomes part of the batching system itself, and only the proper valve will open when a batch is started.

The line selector can be used in these ways:

- To divert the output from a single batching system output to one of multiple vessels either as part of the batching system or as an independent system that is just for output diverting.

- To select one of multiple ingredients as input into the batch control system.

The line selector is most commonly used with the EBV ball valves or ESV solenoid valves mentioned above. It can also be used on air-operated valves by controlling the power to the air solenoid valve on the pneumatic actuator.